Build#

Welcome to the build guide for Helium's DIY kit. We hope you have a great time putting this module together and a wonderful time using it.

Please read all instructions thoroughly before starting. If you have questions or run into trouble please reach out to us on discord or drop us an email at support@winterbloom.com.

Some soldering experience is helpful but not required. If it's your first time soldering we recommend reading through Adafruit's guide to excellent soldering.

This build takes around one hour to complete.

Tools required#

Before you begin, make sure that you've got:

- Safety glasses. Yes, really. A pair like these are fine.

- Proper ventilation, like this small filtered fan.

- A temperature-controlled soldering iron, like this Hakko or the Pinecil. It is very important to use a temperature-controlled iron, since unregulated irons can easily get hot enough to damage components. You should set your iron temperature based on your solder manufacturer's recommendations.

- Solder. We recommend Adafruit's SAC305 solder or Kester 275 K100LD.

Flux

We suggest using solder with "no clean" flux. If you use a different kind of flux, be sure to carefully clean the flux residue off based on the guidelines provided by the manufacturer of your solder. Take special care with the LEDs and potentiometers, as they can be damaged by water and flux cleaners.

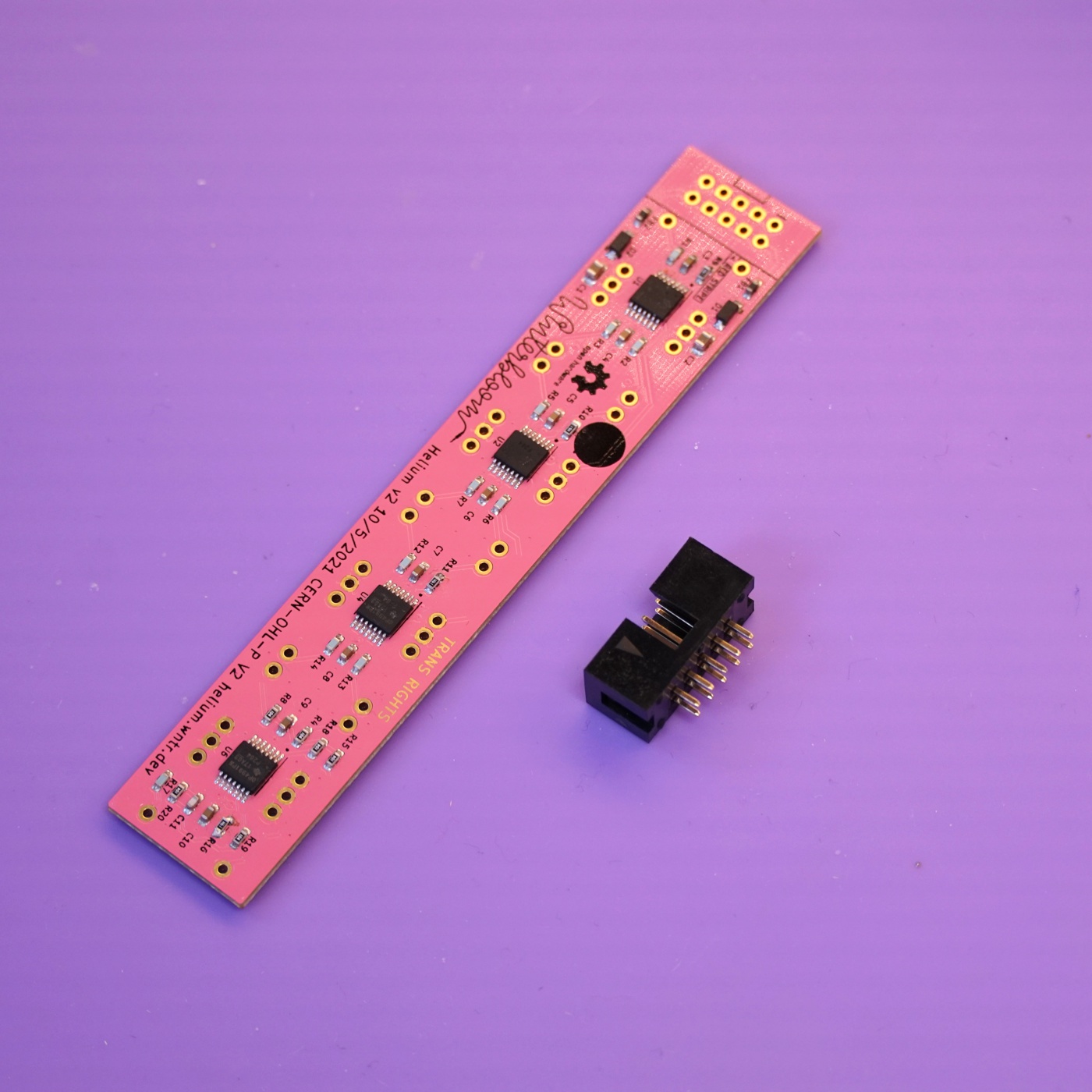

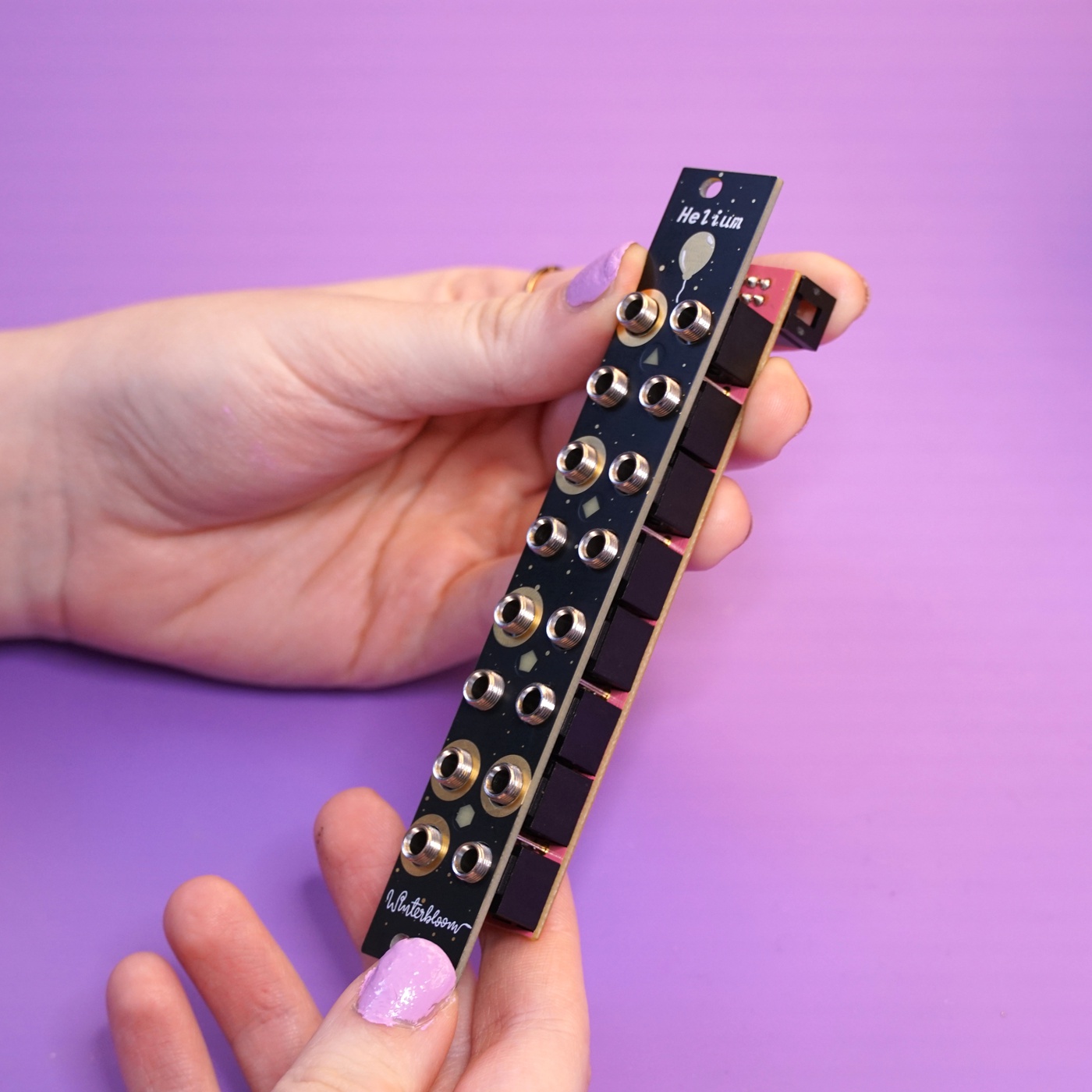

Kit contents#

Your kit should contain the following items. If any are missing please email us at support@winterbloom.com.

- (1) Mainboard

- (1) Front panel

- (16) 1/8" jacks

- (16) Hex nuts for the 1/8" jacks

- (1) Eurorack power header

- (2) Rubber bands

Soldering the power header#

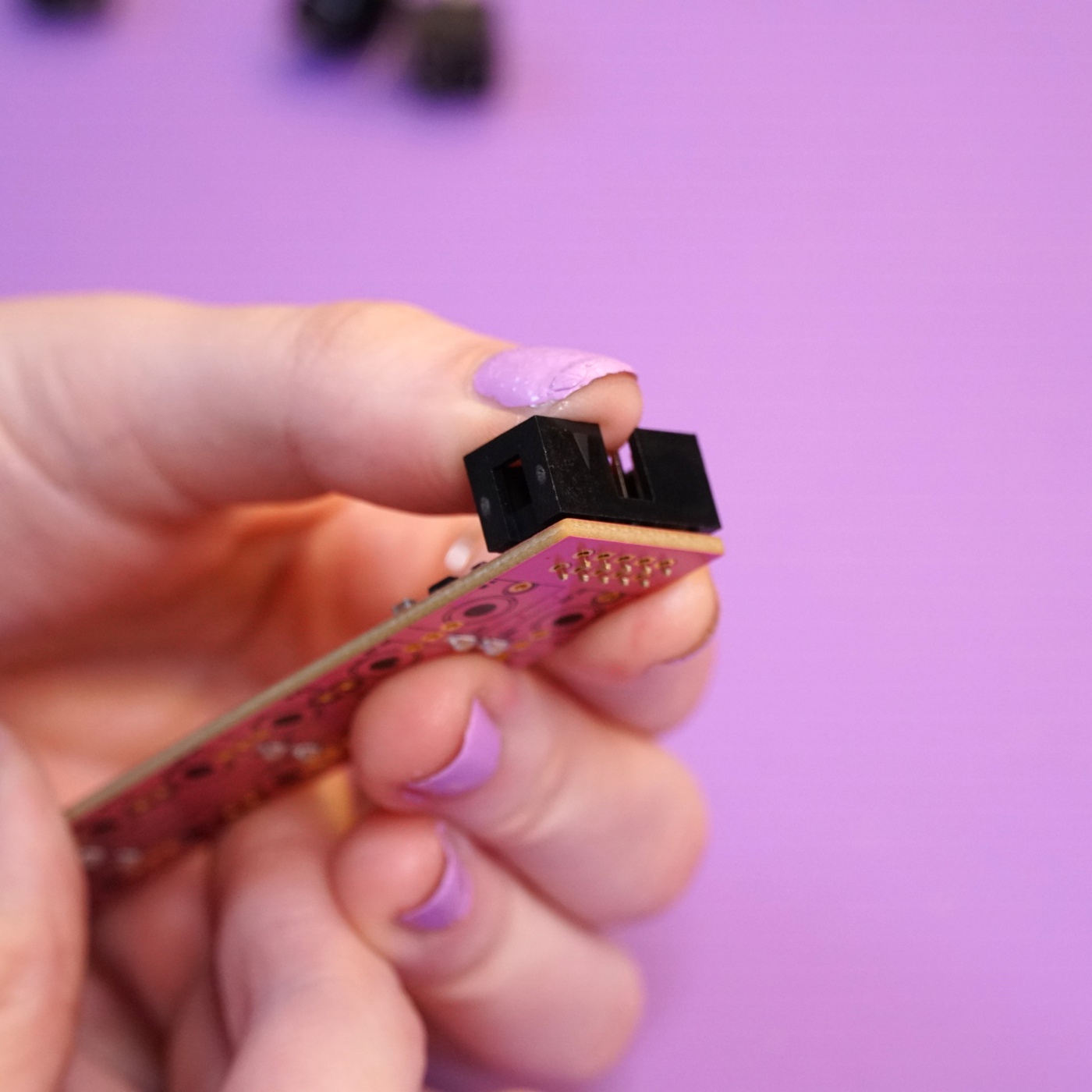

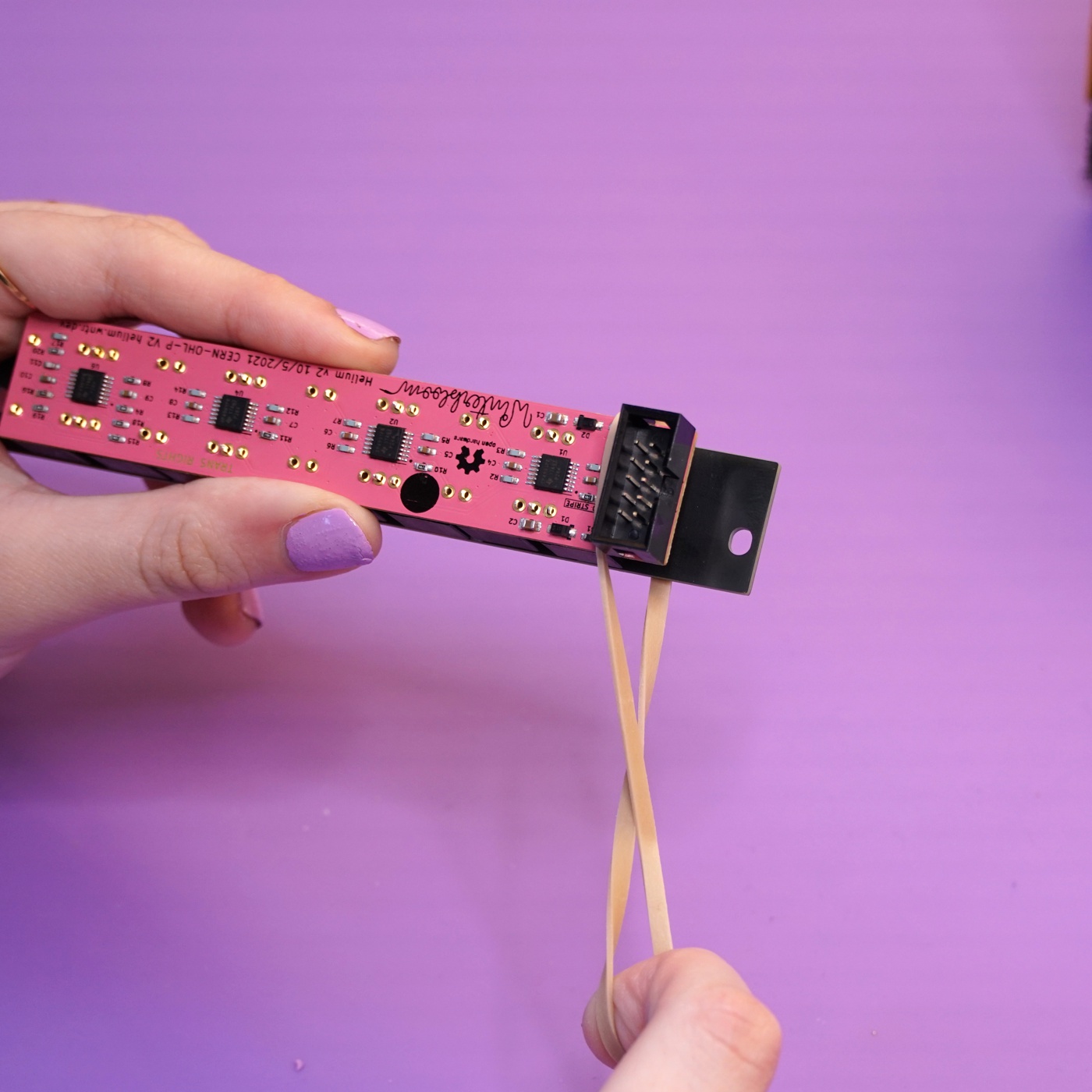

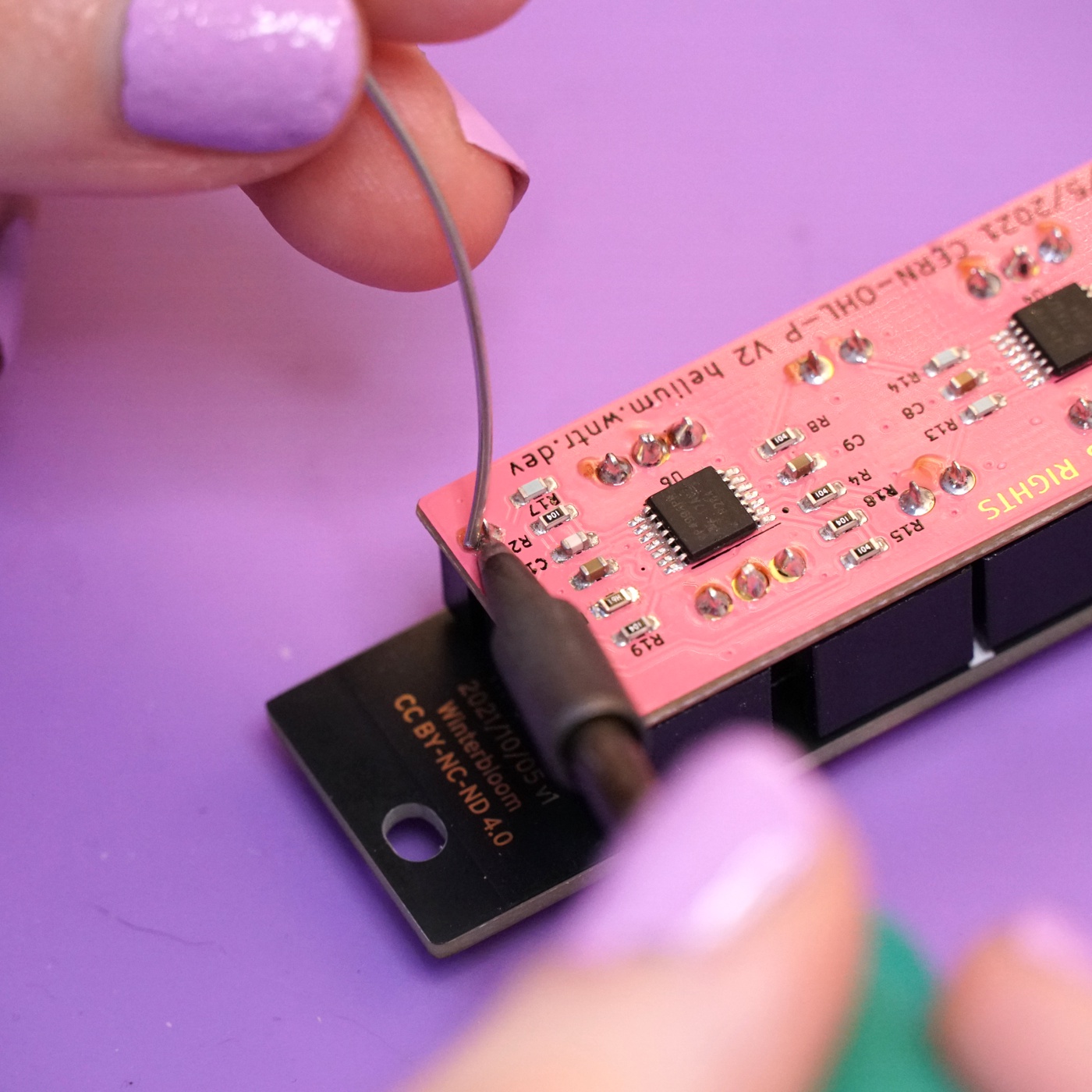

Your first task is to place and solder the power header to the mainboard.

Place the power header onto the back side of the mainboard, being careful to align the notch in the header with the drawing on the board. The power header fits snugly, so you might have to give it a little pressure to push it all the way in.

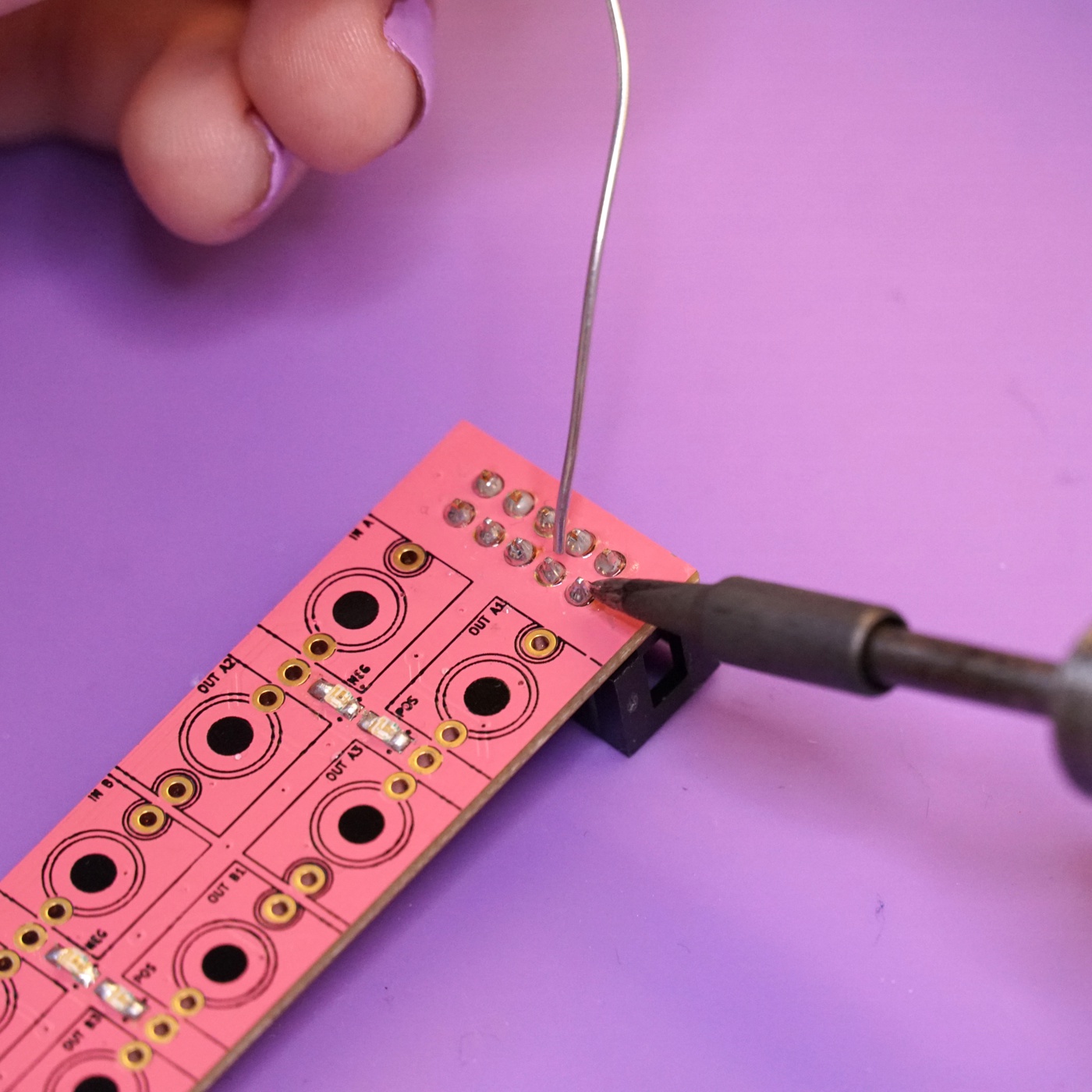

Flip the board over to the front side and solder the header's 10 pins.

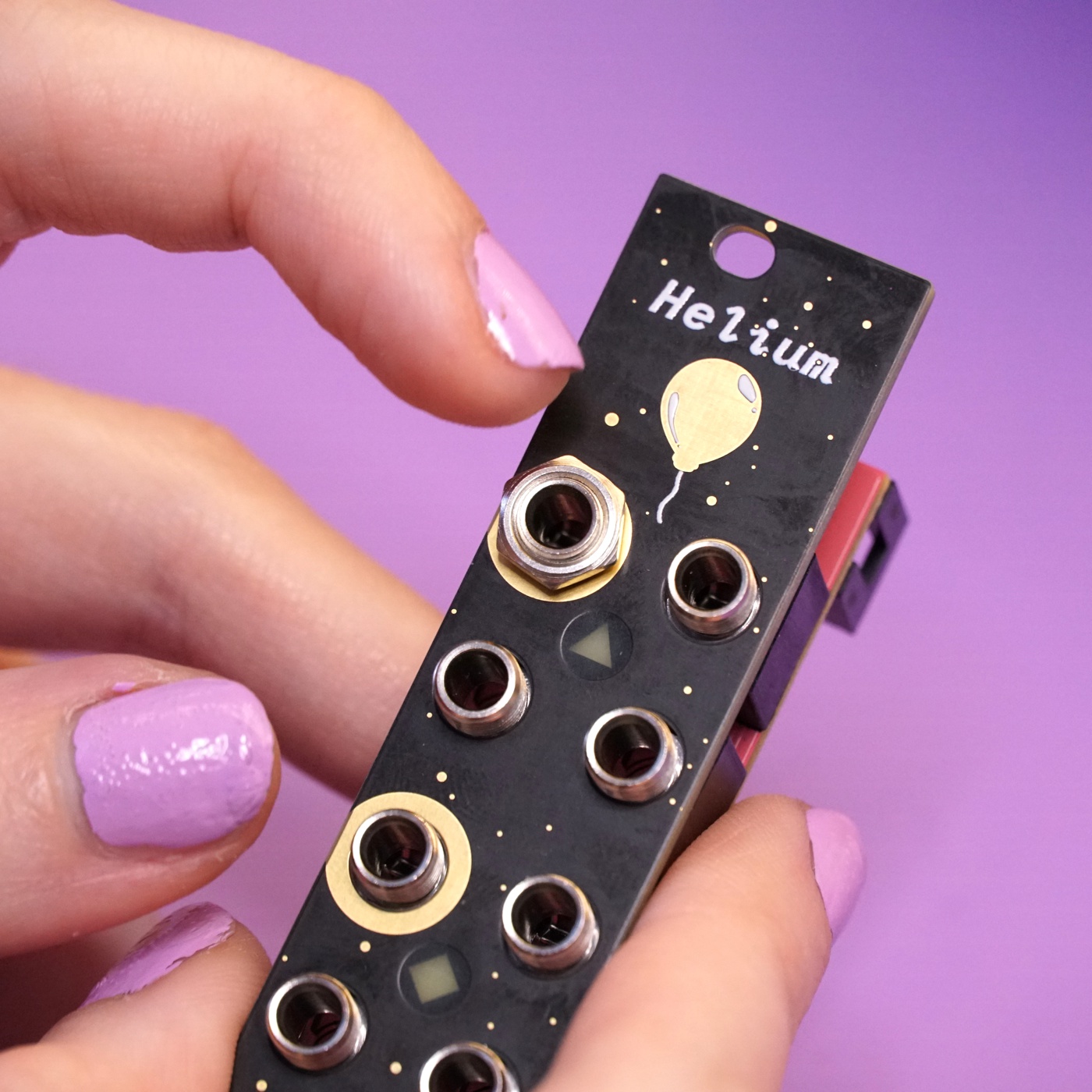

Placing the jacks#

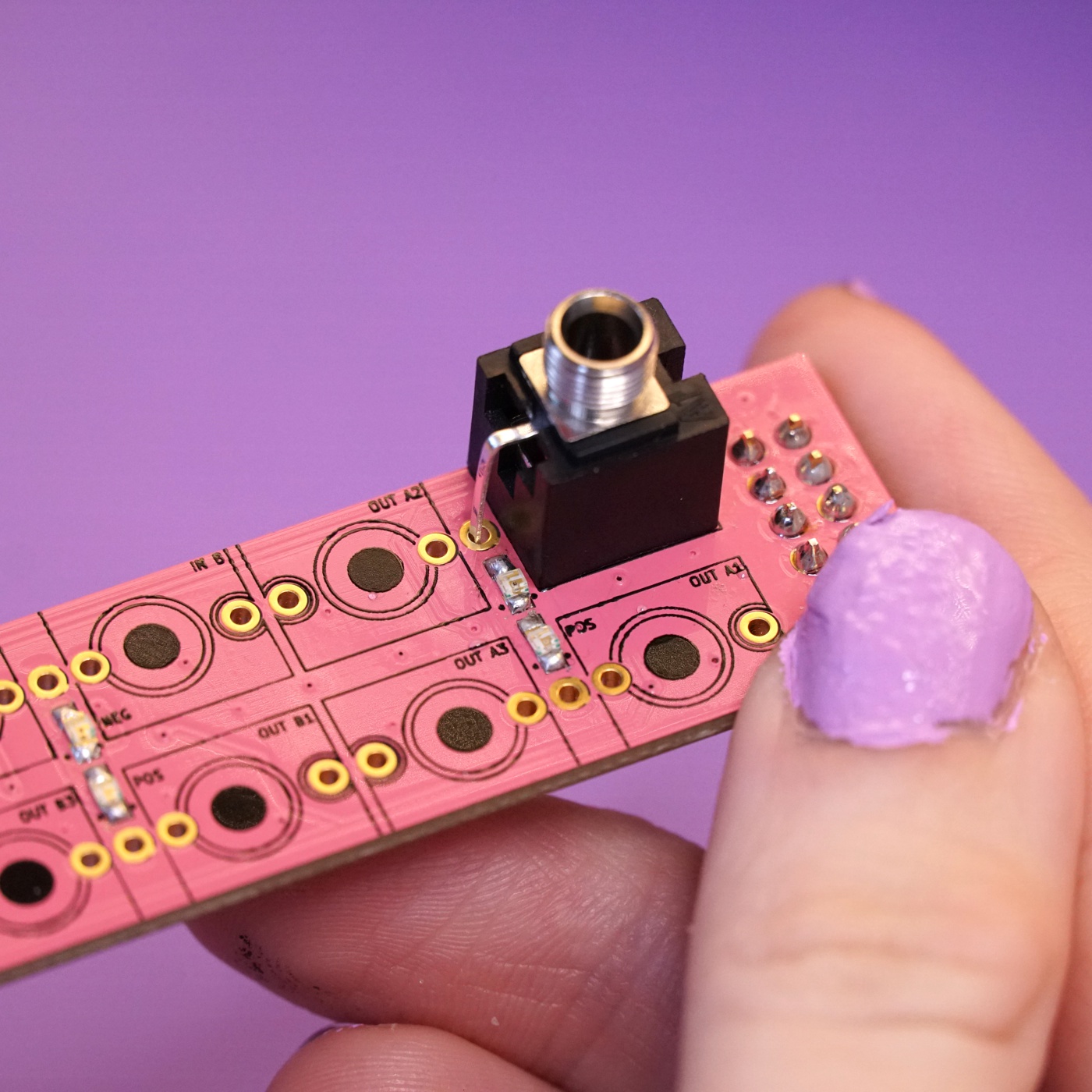

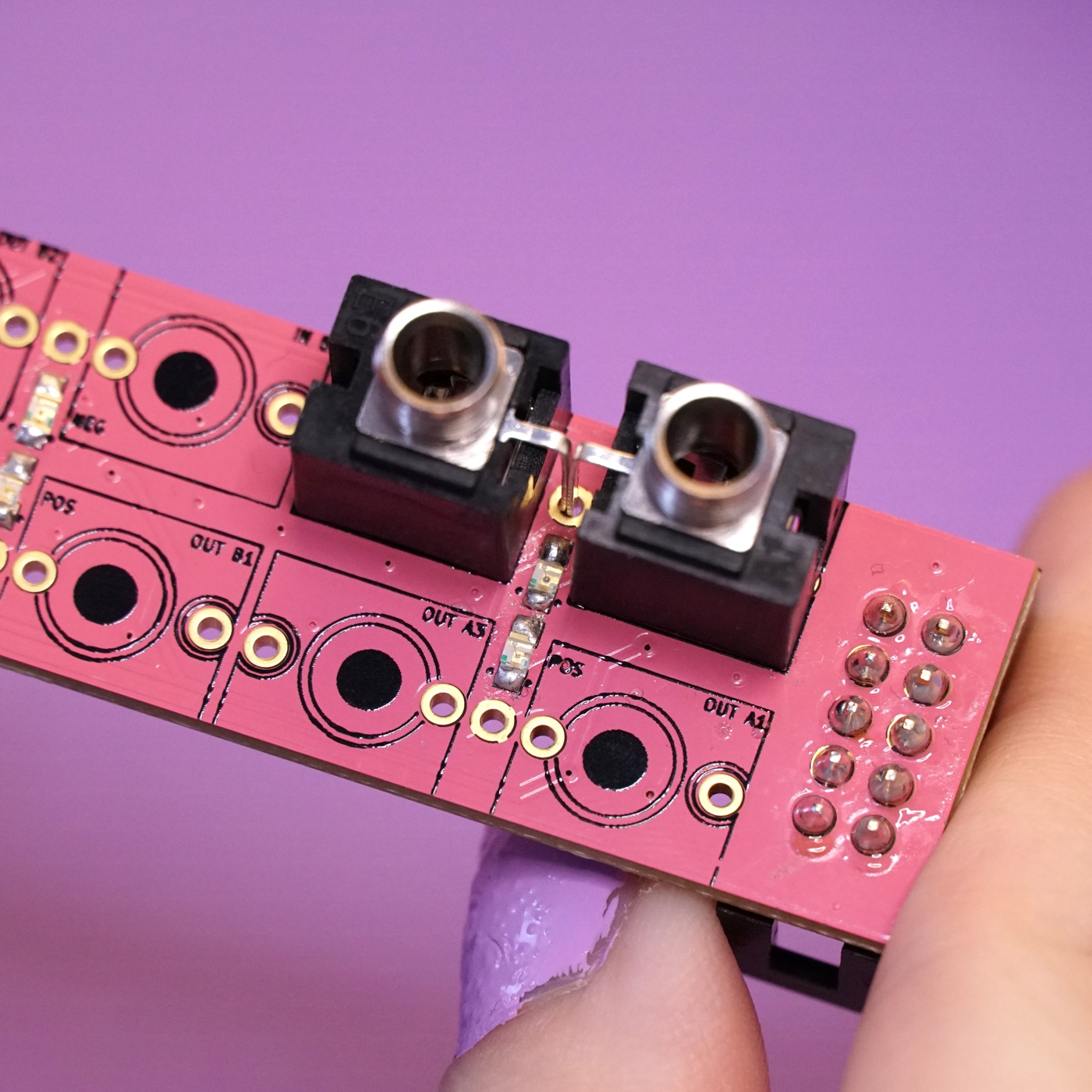

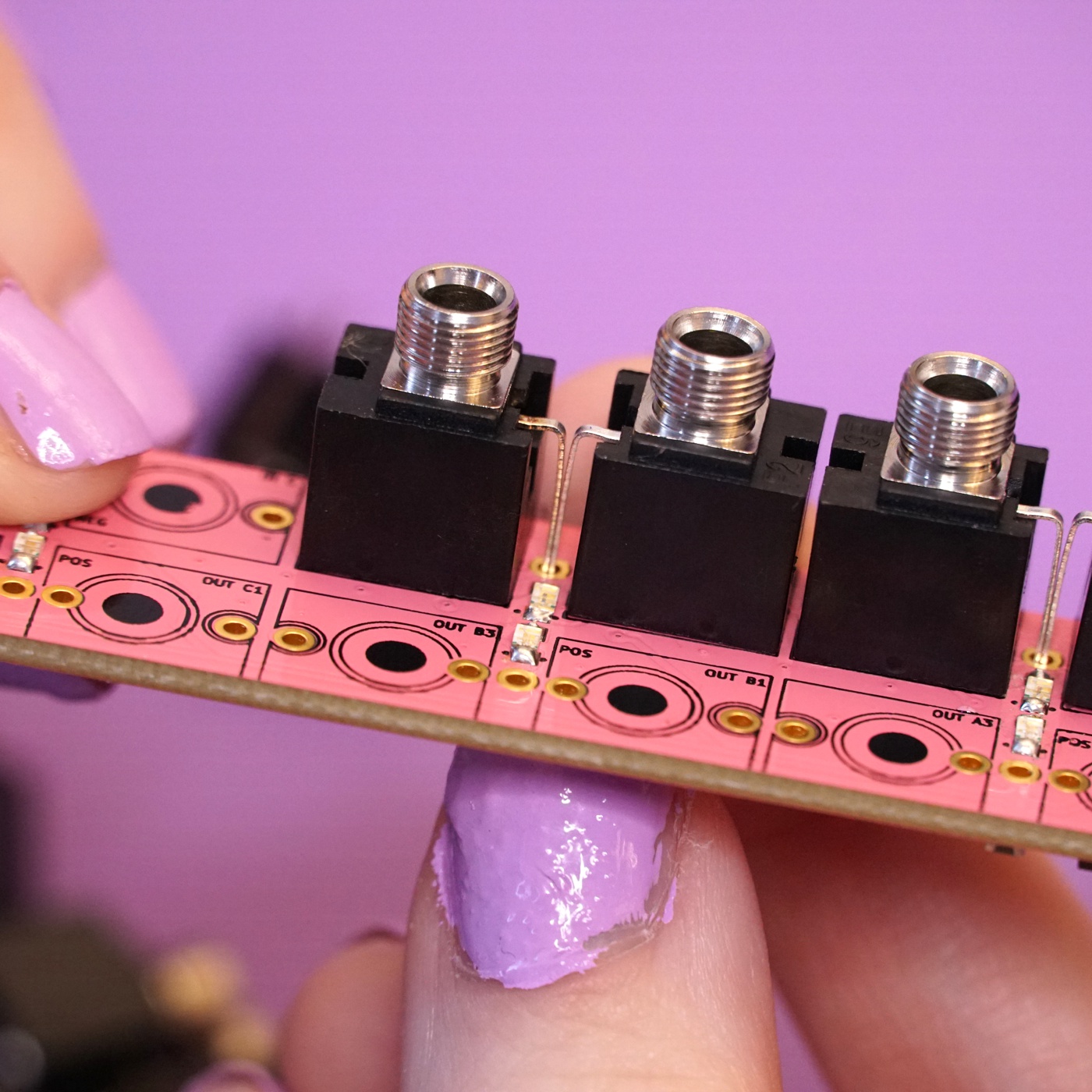

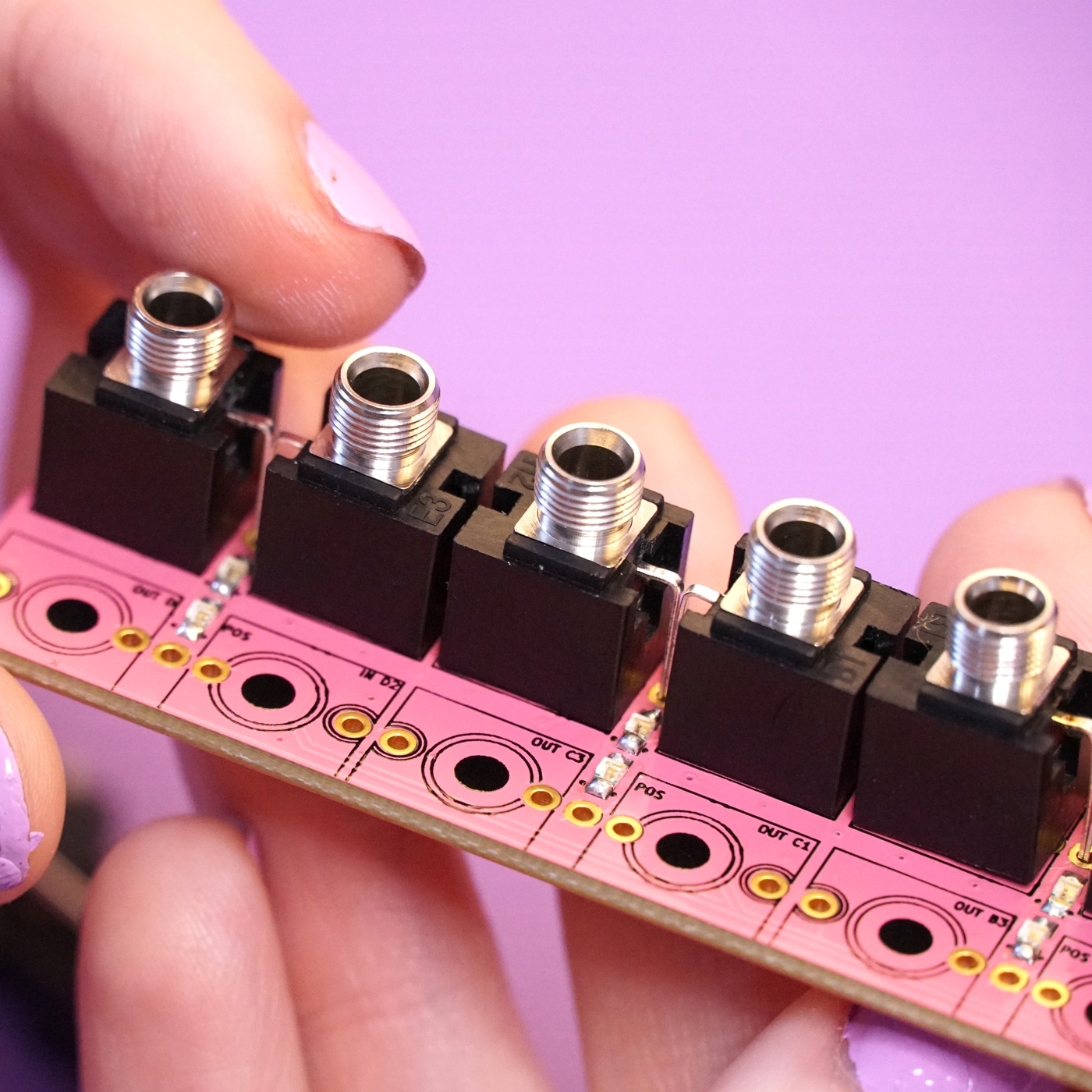

Next up is placing the sixteen jacks on the front side of the mainboard. Start by placing the first jack on in the space labeled In A. Place it according to the drawing on the board, with the third, bendy leg going into the adjacent hole.

The second jack is a bit trickier. Place it into the space labeld Out A2 but in the opposite orientation of the first jack. Place the third leg into the same hole as the first jack's third leg.

Continue this pattern for the third and fourth jacks in the spaces labeled In B and Out B2. The third and fourth jacks will have their third legs placed into the same hole.

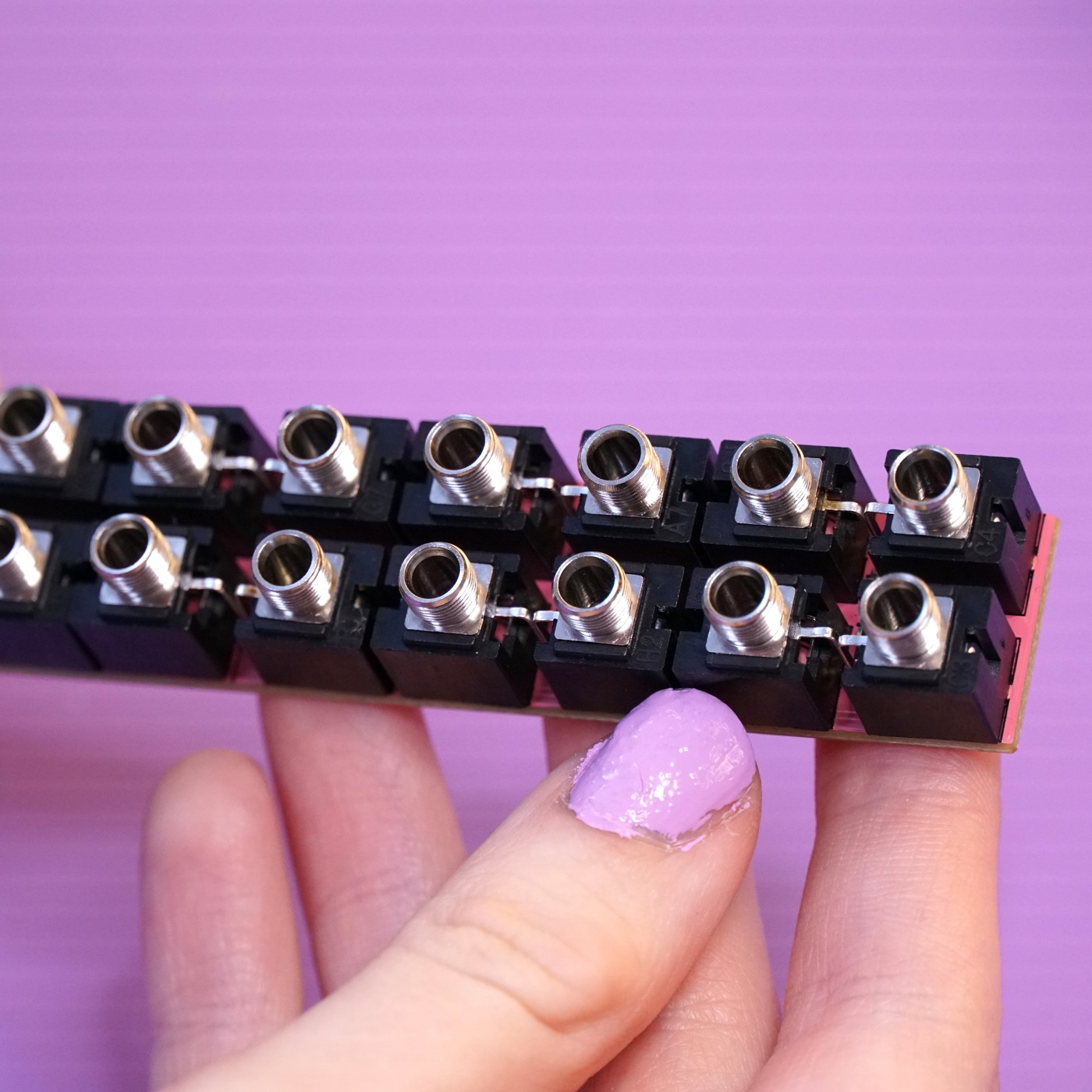

Likewise for the remaining jacks. Continue the pattern of alternating orientation and sharing the hole for the third leg until all jacks are placed.

Using the front panel as a jig#

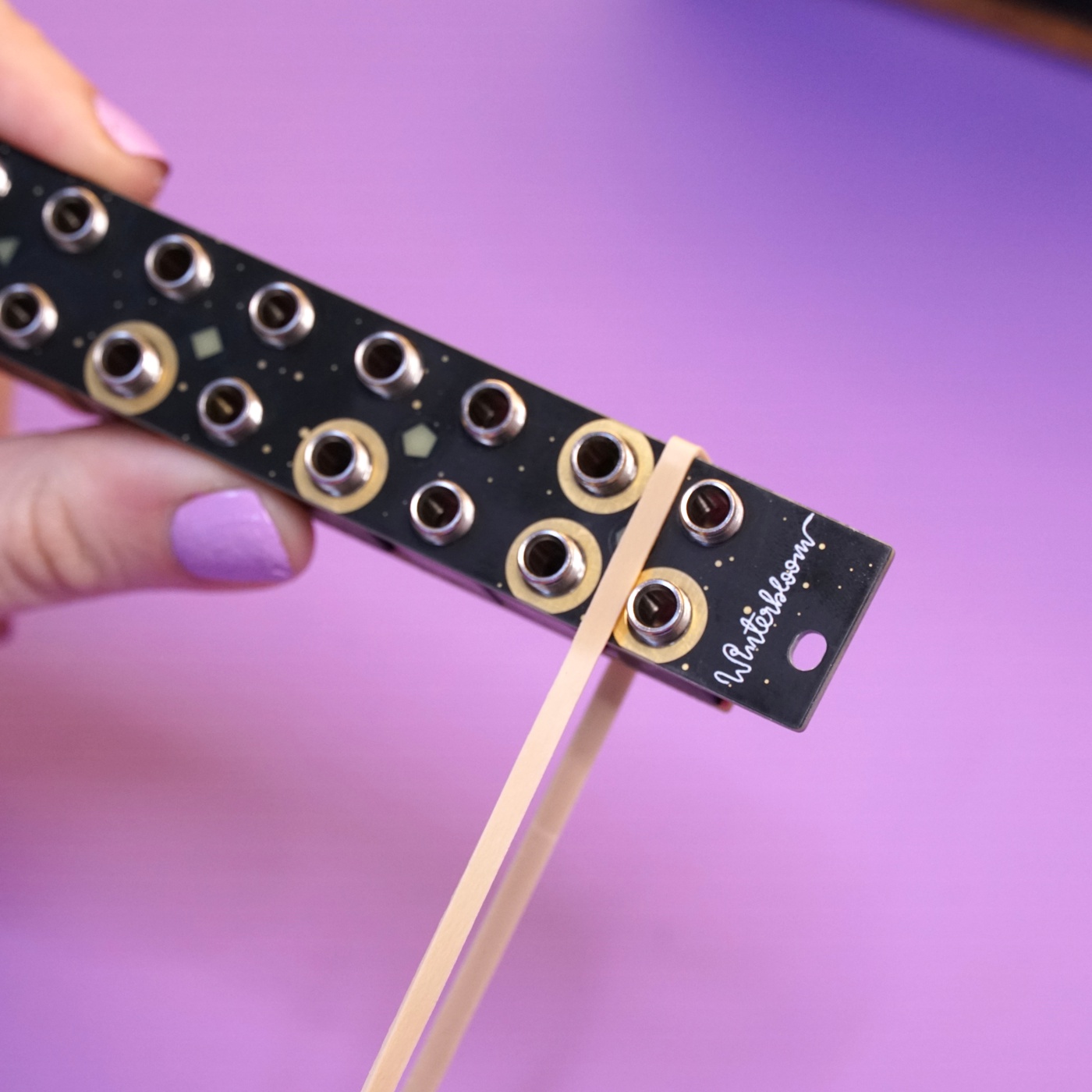

Since the jacks need to peek through the front panel, you can use it as a jig to make sure everything stays in the right place while soldering. Carefully line up the front panel's holes with the jacks and push the front panel on.

Then, use the two rubber bands to temporarily hold the front panel on while you're working on it. You'll need to double- or triple- over the rubber band to get it tight.

Put the two rubber bands on opposite sides of the module so that everything is held down snugly.

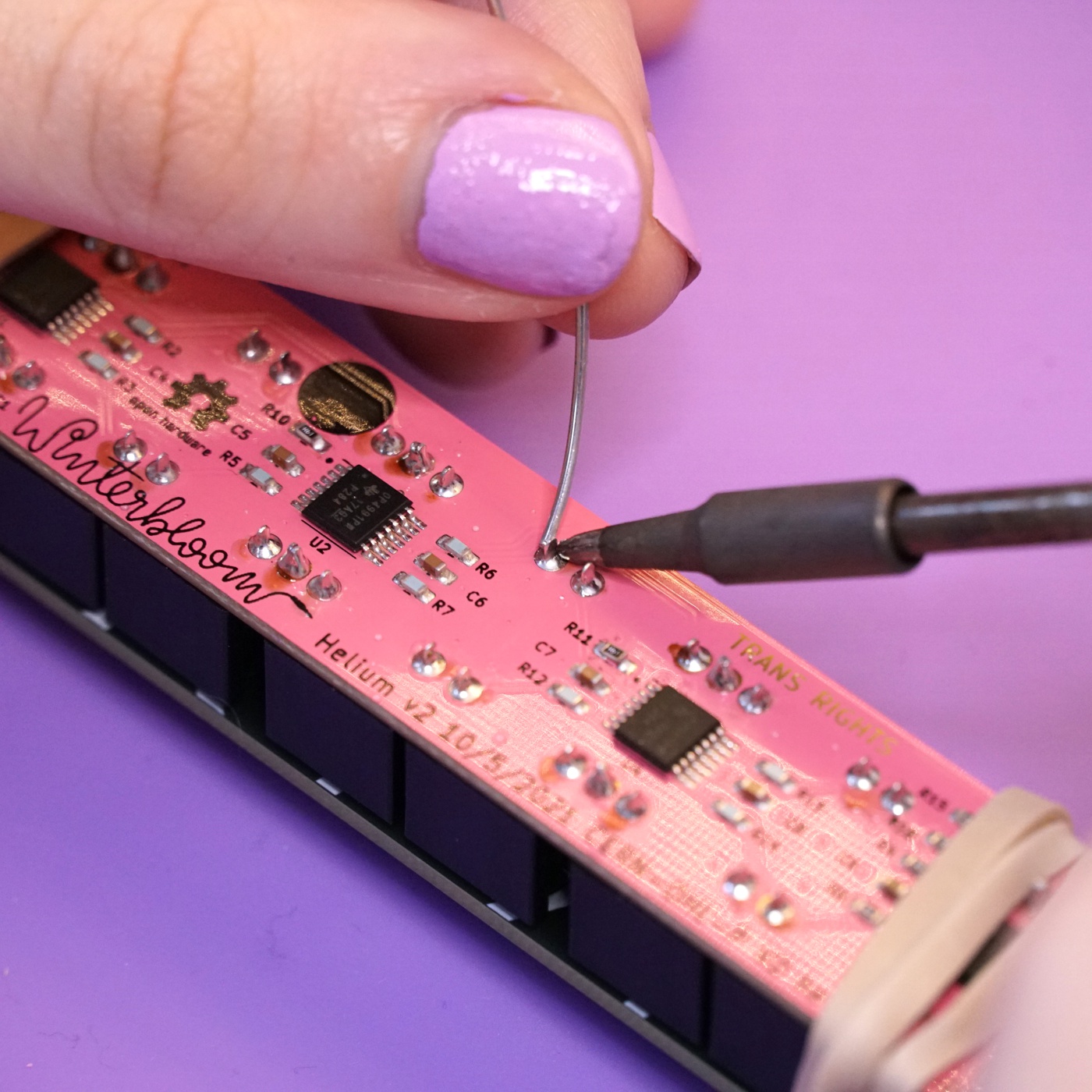

Soldering the jacks#

With everything held in place, you can now flip the module over and solder all of the jacks in place. As you go, take a moment now and then to check that everything is flush with the panel and mainboard.

Once you've got most of the soldering done, you can move the rubber bands out of the way to get to the holes that they were covering up. You won't need the rubber bands again after this step, so feel free to give those a new purpose in life somewhere else.

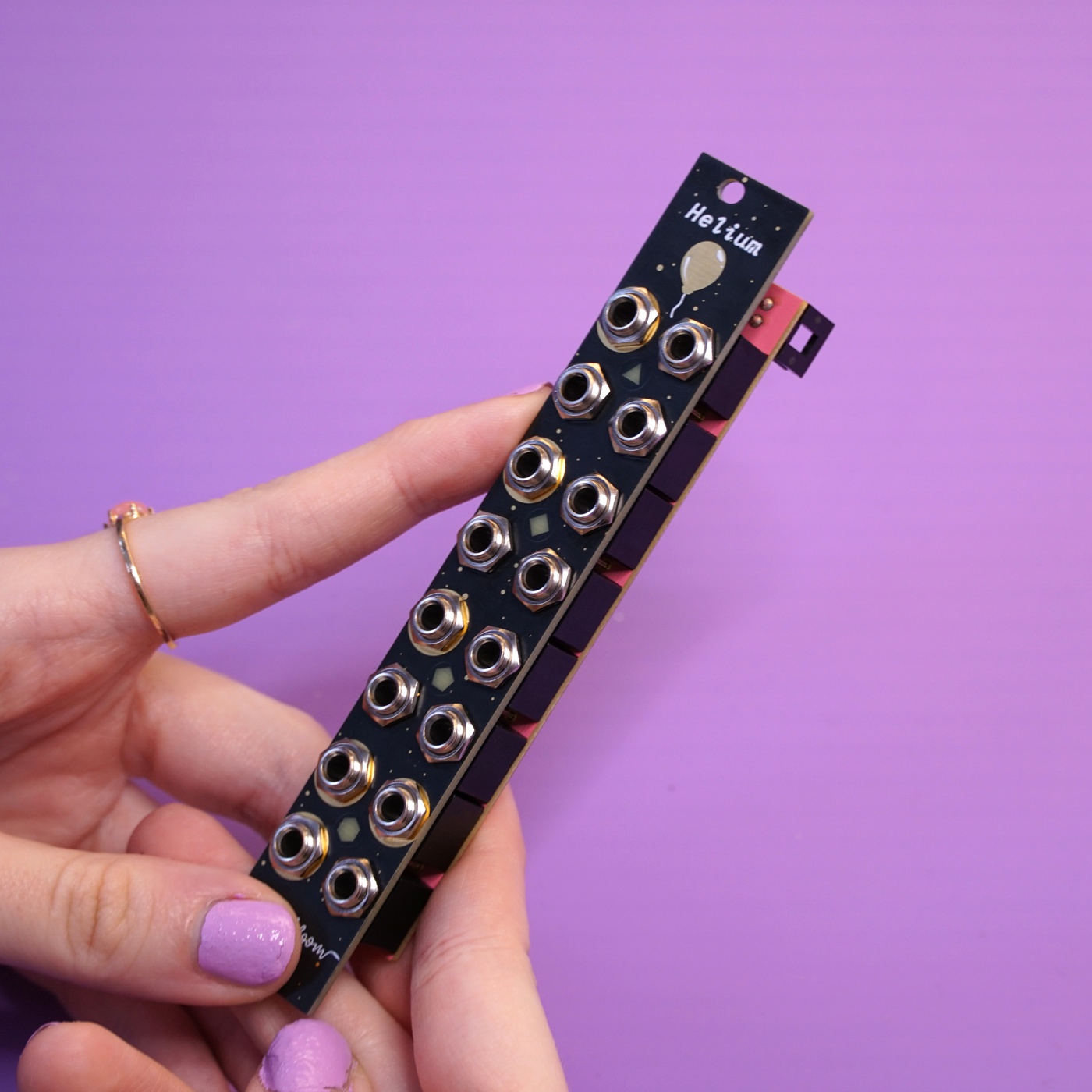

Putting the panel on#

The last step it to place Helium's lovely panel on and secure it with the hex nuts. You don't need to over-tighten the hex nuts, finger-tight is fine.

All done#

Congratulations! You've finished your very own Helium!

Now that it's all put together go check out the User's Guide and please show us your work by tweeting at @wntrblm or tagging @wntrblm in your instagram post.